Boca Build 2.0 Geared Sliding Puzzle Part 1: Design

Boca Build 2.0 Geared Sliding Puzzle Part 1: Design

Dec 18, 2017

Chad B.

My next project for Boca Bearings will be a sliding puzzle similar to the the ones seen in Cogs (skip ahead in the video about 40 sec). It is based on the picture sliding puzzles where you have to slide several panels around to un-jumble an image. Check out Instructables for an example of how to make a sliding wooden puzzle.

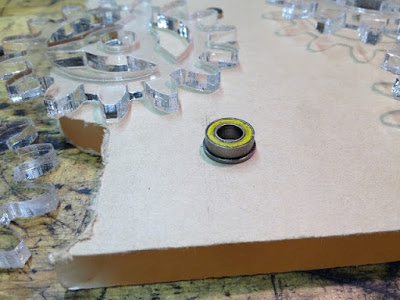

This design is in an early state of development, it is only a mock up and will ultimately be wooden or 3d printed cogs with wood panels. At the beginning of a design I usually jump between arranging physical objects and drawing them in the computer using Rhino. For this build I laser cut several gears out of acrylic, fit them with Boca bearings and placed them on a 12" x 12" piece of acrylic I had sitting around.

This is just a bolt acting as the shaft but it will be machined from scratch with an area to mount to a wood panel.

The bearings I will be using are 1/4" ID, 1/2" OD with a shoulder that allows it to seat into the gear without falling through.

The post will mount to a 3" x 3" wood panel (not shown here) that will slide around. The user will move each panel by this post so it must be secure. Since the post will be mounted to the panel and and not the gear, this should allow the panel to move more smoothly with out tilting the gears, causing it to jam.

I will use a lock washer or thread locker and a washer to keep the gear from falling off the front. I would like to showcase the bearings but they will be mostly covered by the hardware that needs to hold them in place.

There will be a main driving gear (far left) mounted to once side that will drive the rest of the gears once they engage with it. This driving gear will turn at a constant rate while the remaining gears will be free-spinning (until they engage with a moving gear).

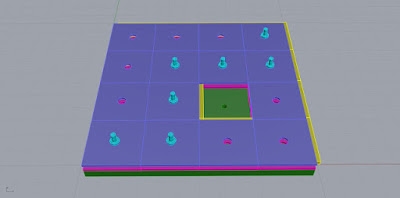

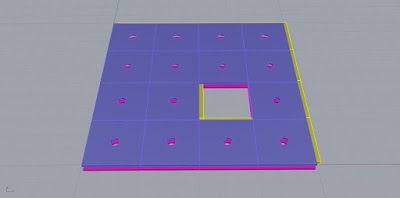

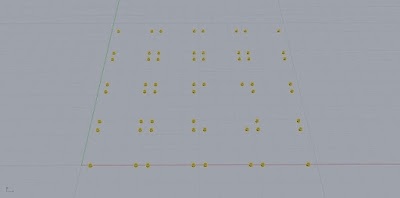

Here is the initial Rhino drawing that shows the gears, posts, panels and base. These colors are only used to show the different components, they will not be the final colors.

Each panel containing a gear will have a shaft that will allow the bearing and gear to spin (seen in light blue). The green square is the background showing through.

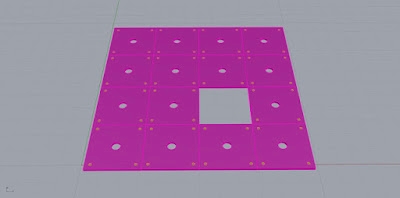

Every panel will be made up of three panels 3" x 3". The top layer (seen in blue/purple) will have a hole for either the gear's shaft or will act as a place for the user to push each panel that does not have a gear.

The second layer of each panel (shown in yellow) will have a lager hole about 1". This will be where the post is sandwiched between the top and bottom layer of each panel. I choose a larger are so it would be more stable when sliding. This second layer will also be offset to the left and towards the top about 1/4". This offset creates a lip that allows each panel to slide along the edge of the panels next to it.

The bottom layer (violet/pink) of each panel will have a hole where a piece of metal will seat to allow each panel to snap to a rare earth magnet mounted to the base (seen below in green).

The green panel is the base or what each panel will slide on. I do not know yet what this will be made from but it will have 16 small holes to allow rare earth magnets to be placed. The final piece will also have sides and mounts for the driving gear and end gear.

On the back of each sliding panel, I am thinking of putting 4 small feet at each corner. These will act as bushings, allowing the pieces to slide more smoothly, with less surface area. These pegs will need to be a softer material than the base so they wear instead of the base. If the back plate is steel, these will be brass, if the back plate is aluminum, I was thinking of using PLA. They will be inset into the bottom layer of each sliding panel.

Now, I will need to begins construction on the wood panels and start machining the posts. At that time I will see how things move around and make adjustments from there.